The Ultimate Guide to Business Labels: What Every Business Needs (and What Yours Might)

Let’s be honest—business labels don’t get nearly the love they deserve. They’re the silent workhorses behind your product’s first impression, your shipping department’s sanity, and your inventory’s organization. Whether you’re running a boutique candle brand or managing a warehouse of widgets, chances are you’re already using labels—and if you’re not, you should be.

But not all business labels are created equal. Some are essential across the board, while others are industry-specific and regulation-required. Let’s break it down.

Labels Every Business Needs (Yes, Yours Too)

1. Shipping Labels

If your business sends anything from A to B, you need shipping labels. These include the recipient’s address, return info, tracking barcodes, and sometimes even delivery instructions. Custom-branded shipping labels? Even better. That’s bonus branding on every box.

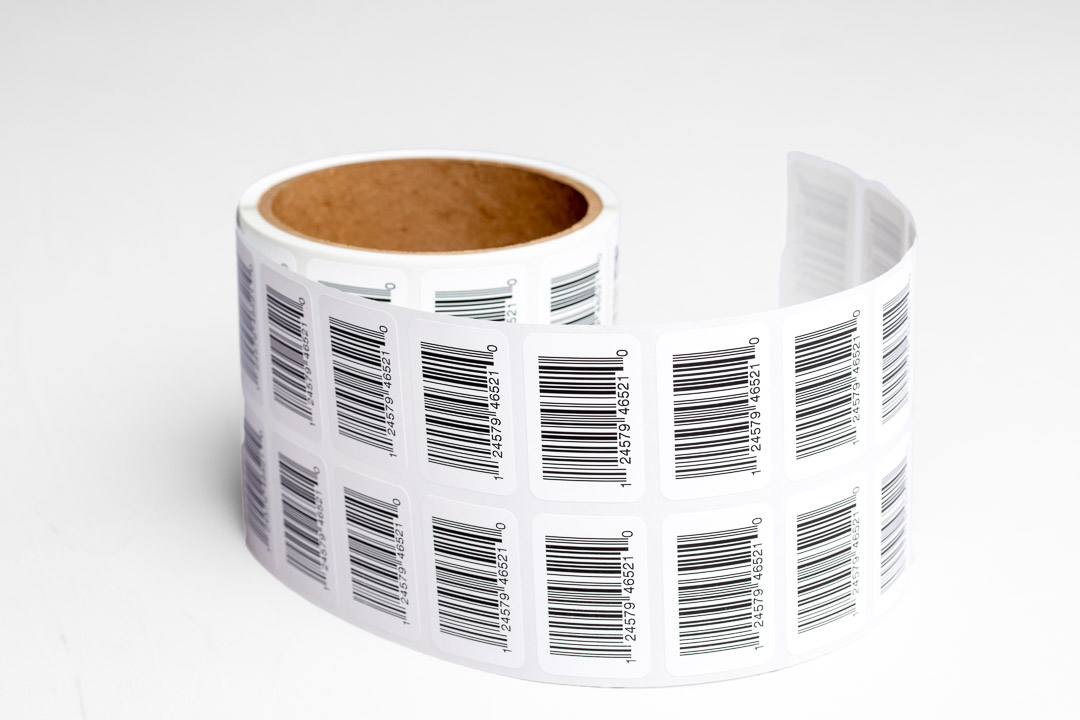

2. Barcode Labels

These little black-and-white heroes are key to tracking inventory, pricing products, and speeding up checkout. From retail shelves to fulfillment centers, barcode labels keep things moving.

3. Product Labels

Your product’s first handshake with a customer. Product labels tell people what it is, who made it, and why they should care. They can include ingredients, usage instructions, warnings, or whimsical branding magic.

4. Logo Labels

Slick little stickers with your brand’s logo—slapped on packaging, tissue, receipts, or even swag. They’re inexpensive, high-impact, and a must for creating a cohesive customer experience.

5. Inventory Labels

Labeling stock with SKUs or QR codes helps track and restock efficiently. They’re especially useful in warehouses and retail stockrooms and can save hours of manual counting and confusion.

Industry-Specific Labels: Because One Size Doesn’t Fit All

Now that we’ve covered the label basics every business should have, let’s dive into some other types of labels common in business. These labels tend to be industry-dependent—required by law, safety standards, or just plain common sense.

Retail Labels

- Sale/Promo Labels – A label that scream deal.

- Window Decals – Eye-catching signage that draws customers in before they even open the door.

- Shelf Labels – For quick identification and clean displays.

- Price Stickers – No customer wants to guess.

Food & Beverage Labels

- Nutrition Facts – FDA-mandated and consumer-trusted.

- Ingredient Lists & Allergens – Transparency is non-negotiable.

- Expiration Dates – Because no one likes a sour yogurt surprise.

- Tamper-Evident Seals – For safety and peace of mind.

Manufacturing & Industrial Labels

- UL/CSA Labels – For certified electrical and safety compliance.

- Warning Labels – High voltage? Sharp blade? Label it.

- Instructional Labels – Show users how to handle, install, or use safely.

- Serial Number Tags – For warranty, support, and quality control.

Why Labels Matter More Than You Think

At their best, business labels aren’t just stickers. They’re tools—tools that build trust, streamline operations, ensure compliance, and elevate your brand. Whether you need thousands of roll labels for shipping or a stack of logo stickers for packaging flair, the right labels do the heavy lifting quietly and consistently.

Curious what labels could do for your business? Contact us today—it might be more than you expect.