CAPABILITIES

Flexography

This printing process uses a relief plate, where the image to be printed is a raised surface. The plate is then wrapped around a cylinder. The substrate then passes between the relief plate and the anilox roll, which coats the plate with ink. Flexography allows for printing on numerous types of substrates ranging from paper, to polyester, to plastic. Flexography is especially good for printing food packaging. Flexography also offers great color retention, which is ideal for those in the consumer-packaged goods. Flexography is typically used for indoor labels and decals with medium to long runs.

Screen Printing

Early screen printers exposed fine silkscreen mesh, to use as an ink-blocking stencil. Today most screen printers use a monofilament, polyester, or nylon mesh. After the stencil is exposed to a screen, the image area is washed out. Then a squeegee is used to push the ink thru the stencil and onto the substrate. Screen printers often use higher mesh screens to produce labels with halftone and finer images. Screen-printing can be printed on virtually any substrate and can produce a thicker layer of ink if necessary. Today screen printing is traditionally used for durable outdoor labels and decals, smaller runs, and oversized decals.

Digital Printing

Printing digitally is the newer technology within the printing industry. This method allows for printers to meet customers’ smaller to medium quantity orders in a more costly and timely manner. Printing digitally has little or no preparation costs, offers variable data, and full color labels. Digital printing can offer small and large format labels.

Label Design & Construction

If you are new to buying or designing labels, there are questions that you might have. What are the best materials for my project? How should this label be best printed? What is flexography anyway? What is roll chart and why does it matter? At the MR Label Co., we will work with you to choose the best materials, ink systems, and print method for your application. First, we will need to know a few things…

How is the label being used?

What is it being applied to? Please be specific. ABS plastic, stainless steel, HDPE, etc.

Will the label be used indoors or outdoors?

At what temperature will the label be used? Perhaps, the label will go in a freezer or be applied to a motor that heats up to 300°F.

Are there any special requirements that will affect the performance of the label?

(Maybe the label is exposed to salt water, cooking oils, or harsh chemicals for instance)

What is the life expectancy of your product?

Are there any special certifications that we have to meet such as GHS, UL, or CSA?

Will you be printing on the label? If so, what is the print method? (laser, ink jet, thermal, dot matrix)

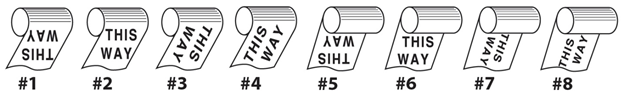

Is the label auto applied? If yes, which way does the label need to come off of the roll? Roll Chart.

Is there a similar label that you like? If so, we would love to see a sample.

Do you have artwork? Will we be creating the art?

What is the estimated annual volume?

Please give us a ring at 1.888.LABELCO to review these questions so that we can help engineer a product specifically for your needs.

Additional Capabilities

Prepress & Graphic Design

DTP Flexographic Plates

Guillotine

Lamination

Thermal Transfer

Barcode Verification

Rewinding & Custom Finishing

Diecutting, Embossing, & Varnishing

Cold Foil

Variable Database Printing

Delam/Relam

Screen Imaging