UL Labeling Essentials

If you’re new to sourcing UL labels, the learning curve can feel steep. UL standards, label categories, compliance rules- it’s a lot to take in. But the good news is this: once you understand the core concepts, UL labeling becomes far more manageable. This guide breaks the essentials down into practical, easy-to-understand pieces so you can make confident purchasing decisions.

What are UL/cUL labels?

UL (Underwriters Laboratories) is an American safety company that develops safety standards for thousands of products used every day. The US and Canada work together to make products safe using testing standards set by each country. For any UL approved product, you will see the UL marking no matter if the product is approved for the US (UL), Canada (cUL), or for both (cULus). These symbols let regulators, inspectors, and consumers know that your product is safe, durable, and compliant. Generally, these types of labels are nameplates that are applied to devices, appliances, and equipment that include instructions and schematics. They are also likely to contain warnings, electrical ratings, and other safety related information.

While the label is evidence of a product complying with standards, it also has strict performance requirements it must meet. The label must stay attached, legible, and intact for the life of the product- even under temperature extremes, gasoline/oils, and other conditions. The requirements for UL labels can be found under UL 969 the Standard for Safety of Marking and Labeling Systems.

Who makes UL/cUL labels?

Only authorized suppliers can produce UL/cUL marked labels.

Every authorized supplier has a UL file number that houses their listings that are searchable through the UL online database. Listings are “systems” that are assigned to a category of how the label will be used. Systems comprise of the material construction (stock, laminate, and adhesive), printing inks, ribbon types, and print method that have been approved for the listing.

These authorized suppliers are audited by UL inspectors on a quarterly basis. The purpose of these audits is to make sure the printers are following the regulations set by UL for safety.

What are common categories of UL/cUL labels?

PGDQ2/8 – Marking & Labeling Systems

- Finished, printed labels approved for specific environments

PGJI2/8 – Printing Materials

- Unprinted or partially printed labels designed for additional printing with UL approved ribbon

PGIS2 – Marking and Labeling Systems, Limited use – Component

- Covers items such as cord tags and placards evaluated for specific end-product standards

How are UL/cUL labels put to the test?

UL doesn’t just certify the adhesive or the film; it certifies the entire construction under real-world conditions. Common durability tests include:

- High/low temperature cycling

- Humidity and water immersion

- Chemical splash exposure (oils, fuels, cleaning agents)

- UV and outdoor weathering

- Abrasion and defacement resistance

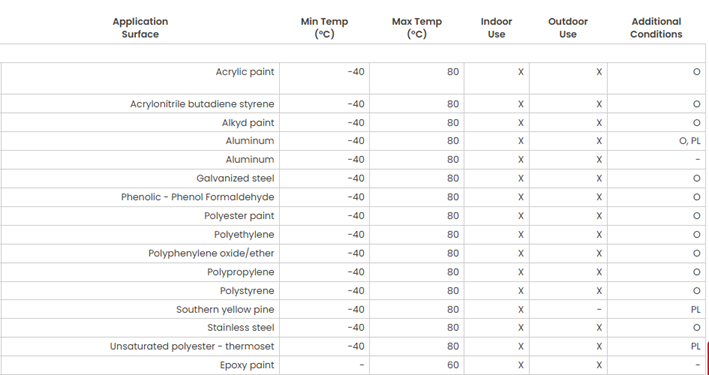

On each UL file you can find the different surface types a construction is suitable for and the service temperature ranges for those surfaces.

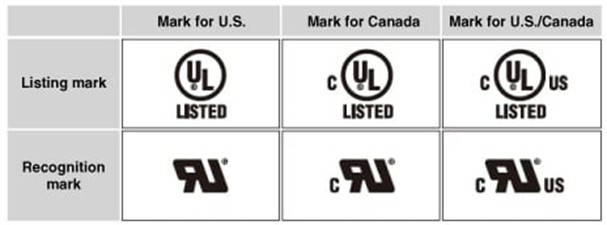

What are UL markings and how are they used?

Using the UL Mark correctly is critical. Depending on your certification, you may need:

- the Listing mark- indicates UL has evaluated product for compliance with applicable safety requirements

- the Recognized Component mark- for components that make up a listed product

- the Classified mark- product has been tested to use for special conditions

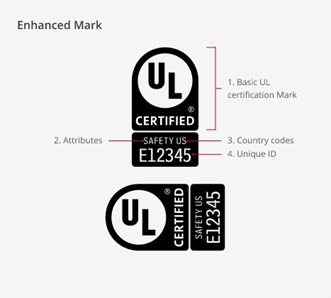

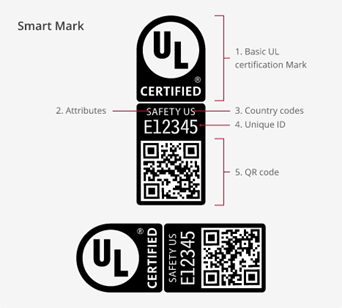

UL also has newer Enhanced and Smart marks that provide more information on them.